In addition to the requirements for raw materials, there are also high requirements for extrusion equipment in the production process of SPC floor, such as screw plasticization, vacuum of the main machine and vacuum barrel enlargement, and twin-screw feeding are required for feeding, film coating device, automatic film feeding, film covering position, automatic deviation correction and automatic plate turning, etc.

If you want to produce high quality SPC floor product, firstly, you have to choose a reliable and experienced extrusion equipment manufacturer who can provide complete SPC floor production line as well as new technology and sustainable service to support your long-term production.

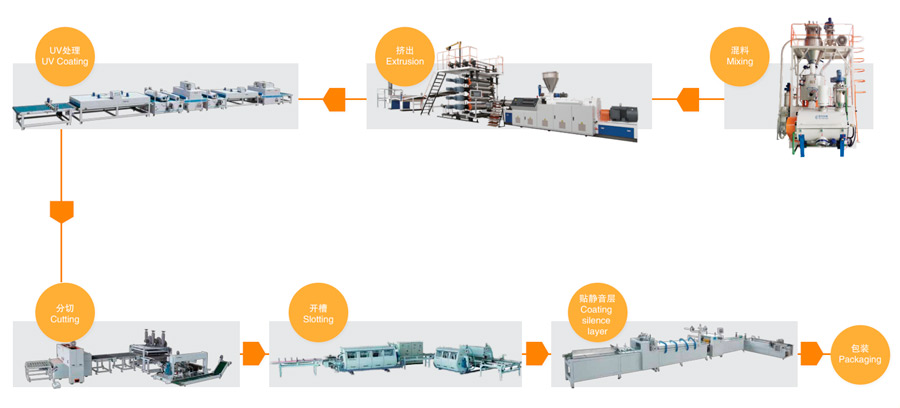

SPC Floor Production Process:

Firstly, PVC base material extruded by extruder, then four roll calendering machine is used to press and paste the PVC color film + PVC wear-resistant layer + PVC bottom film on the PVC base material at one time, and finally the mute layer is pasted on the bottom of the PVC base material. The whole manufacturing process is simple, and the fitting is completed by heat, without glue.